In

this "how to" chapter, we deal with the mounting of the AN/AVS-9 bracket to the

helmet and replacing the Catseye mount. Second part deals with the mounting of the bracket

to the HGU-55/P. Before giving the technical information on how to replace the night

vision equipment, a little rundown of sets that has been in use:

AN/AVS-6 - Aviator’s Night Vision Imaging System (ANVIS) is the USN/USMC

rotary-wing aircraft NVG. There are currently over 3700 ANVIS NVG’s in service, with

an inventory objective of 4725. The Army and Air Force also use ANVIS. The AN/AVS-6 is a

lightweight, self-contained, helmet-mounted, direct-view binocular image intensification

device. ANVIS is powered by 2 AA alkaline batteries. It is a passive detection device

designed for use with military helicopters and KC-130 aircraft as a pilot aid during night

time, low-level terrain flight.

Used on H-53, H-1, H-46, H-3, H-60, KC-130

MXU-810/U - “Catseye” was

one of two NVG’s used in USN/USMC tactical (fixed-wing) aircraft. Catseye is

phased-out and replaced by AN/AVS-9. All Catseye NVG’s will be out of service by

2000. The MXU-810/U “Catseye” Night Vision Goggle Sensor (NVGS) was a

projected-image, helmet-mounted binocular image intensification device. Catseye utilised

an optical combined eyepiece to present the intensified image to the user. Catseye was

powered by one 1/2 AA lithium battery. It was a passive detection device designed for use

with military fixed-wing aircraft as a pilot aid during night time operations.

Was used on F/A-18, F-14, AV-8B.

AN/AVS-9 - AN/AVS-9 is the new

USN/USMC tactical (fixed-wing) aircraft NVG. These goggles are currently being delivered,

with over 600 fielded to date and an inventory objective of 1450. AN/AVS-9 is also used by

the U.S. Air Force. The AN/AVS-9 is a lightweight, self-contained, helmet-mounted,

direct-view binocular image intensification device. AN/AVS-9 is powered by one 1/2 AA

lithium battery. It is a passive detection device designed for use with military

fixed-wing aircraft as a pilot aid during night time operations. Used on F-18C/D/E/F,

F-14A/B/D, AV-8B, F-18A/B (Pre-Lot 12 w/NVG Kits).

PART 1

SUBJECT: AN/AVS-9 (V), DETACHABLE HELMET MOUNTING PLATE ASSEMBLY INSTALLATION ON THE

HGU-66/P, HGU-68(V)/P AND THE HGU-85(V)/P HELMETS. (WUC 96C1P00)

PURPOSE OF DIRECTIVE:

The purpose of this directive is to provide P/N 264317-3,

AN/AVS-9(V) Detachable Helmet Mounting Plate Assembly installation instructions. This

change will provide aircrew members a means of attaching the AN/AVS-9(V) Night Vision

Goggle (NVG) to their protective helmet. Use of this NVG will provide a significantly

improved Field of View (FOV), thus enhancing overall aircrew night mission performance.

This technical directive was proposed in reference (a), approved by reference (b) and

authorized by reference (c).

APPLICATION:

1. BASIC EQUIPMENT:

a. The following equipment shall be modified by service activities:

Helmet Assembly, Medium HGU-66/P 97247 (NOTE 1) (NOTE 1) 750*

Helmet Assembly, Large HGU-66/P 97247

Helmet Assembly, Extra Lg HGU-66/P 97247

Helmet Assembly, Medium HGU-68(V)/P 97247 89D7981-1 01-393-1174 6000*

Helmet Assembly, Large HGU-68(V)/P 97247 89D7981-2 01-393-1182

Helmet Assembly, Extra Lg HGU-68(V)/P 97247 89D7981-3 01-393-1184

Helmet Assembly, Medium HGU-85(V)/P 97247 89D7981-7 (NOTE 2) 2500*

Helmet Assembly, Large HGU-85(V)/P 97247 89D7981-8

Helmet Assembly, Extra Lg HGU-85(V)/P 97247 89D7981-9

*Total quantity in use of each type helmet.

NOTES:

1. HGU-66/P Helmets one time procurement so no Part Number or NIIN assigned.

2. HGU-85(V)/P Helmets one time procurement so no NIIN assigned.

SUPPLY DATA:

1. REQUIREMENTS FOR BASIC EQUIPMENT:

a. Government Furnished Material (GFM):

1 264317-3 Helmet Mounting Plate Assy (extended travel)

1 265030-3 Bracket Kit, Helmet

b. Other Material Required:

1 GGG-K-275 Hex Key Set 00-439-8988 (2) $ 3.40

A/R Tape, Masking 00-283-0612 (2) N/A 1 inch wide

A/R Tape, Pressure 00-074-5124 (2) * N/A Sensitive, 1-inch wide

A/R MIL-A-46106 RTV 102/732 00-877-9872 (2) N/A Adhesive

1 89D7697-1 Lightweight 01-319-8962 (2) $49.76 Visor, Clear (for night) (NOTE 1)

(MBU-23/24/P trim)

1 89D7697-2 Lightweight 01-319-8961 (2) $48.57 Visor, Neutral (for day) (NOTE

1)(MBU-23/24/P trim)

*Tape required for step visor.

NOTE

One visor is required when using the MBU-23/24/P Oxygen Mask for only the HGU-68/P or

HGU-85/P Helmets.

c. Parts/Material Removed and Disposition:

1 88B7586-2 EEU7/P Helmet 8475-01-360-7285 (A) visor assembly

1 00-067-01 Helmet Plate 5340-99-780-0911 (A) assembly

DETAILED INSTRUCTIONS:

1. Basic Equipment:

NOTE

The Bracket Kit P/N 265030-3 contains required hardware to attach the P/N 264317-3 helmet

mounting plate to the selected helmet; four #6-32 hex head screws, four lock washers, left

hand- mounting bracket (thick concave bracket), right hand-mounting bracket (thin concave

bracket) and two interior backing plates. Ensure aircrew member has a properly fit helmet

assembly prior to incorporation of this directive.

a. Place all removed

components in a VIDS/MAF bag marked with the aircrew-members identification number. Set

aside and retain for future reconfiguration, as necessary.

NOTE (new note)

Prior to removal of the MXU-810/U Helmet Plate, outline the position of the Helmet Plate

on the helmet shell exterior surface to facilitate reconfiguration.

b. For HGU-66/P and HGU-85(V)/P helmets: Unsnap and remove visor; set aside clear of work

area for reinstallation. Detach existing MXU-810/U Night Vision Goggle helmet plate by

removing the three screws and flat washers along with fabric cover from the underlying

T-nuts. Proceed to step e.

c. For HGU-68(V)/P: Lower

visor to expose the visor locking guide-locking plate. Lift locking plate tab and slide to

open position to expose rounded hole in locking guide slot. Raise visor to full up

position placing visor lock knob in the rounded hole of locking guide slot. Rotate visor

lock knob 1/4 turn clockwise to disengage locking key from visor locking guide slot and

remove lock knob. Remove visor by sliding aft until clear of tracks.

d. Detach visor-locking guide by removing six attaching screws. Detach left and right

visor tracks and all external components by removing six attaching screws.

e. Detach ear cup assemblies from pile fastener tape on helmet shell interior and position

clear of work area.

f. Remove the screws and flat washers from the underlying lock washer and flanged nut

securing the chin/nape strap to the rear of the helmet, reassemble removed components on

grommeted ends of chin/nape strap to prevent twisting or position shift during

maintenance.

g. For HGU-66/P helmets: Position helmet inverted on workbench with the helmet brow

closest to technician. Grasp two fabric liner release loops on rear half of custom fit

liner, apply inward and upward pressure on loops, maintain pressure and move liner up and

out of rear of helmet shell. Slide front half of custom liner toward rear of helmet shell

and remove, set both halves aside for reinstallation. Proceed to step j.

CAUTION

The energy absorbing liner is easily damaged, use extreme care during removal and handling

procedures.

NOTE

Prior to removal of the energy absorbing liner, mark the centerline of the liner and the

helmet shell edge roll at the brow and nape to ensure correct re-positioning of the liner

during replacement.

h. For HGU-68(V)/P, HGU-85(V)/P helmets: Position helmet inverted on workbench with brow

of helmet closest to technician. Insert a thin flexible metal spatula (a 12-inch x 1-inch

metal ruler may be used) between inner surface of helmet shell and energy absorbing liner

at the center rear of the helmet, apply inward and upward pressure on liner, until there

is enough clearance to grasp energy absorbing liner with free hand.

NOTE

Rotate liner approximately 90 degrees left or right to clear ear cup cavity edge roll and

permit complete withdrawal from helmet shell

i. Maintain inward and upward pressure on liner and continue to move it up and out of

helmet shell.

j. For HGU-66/P and HGU-85(V)/P helmets: Invert helmet and place 1 inch x 1 inch squares

of pressure sensitive tape on the three t-nuts and underlying lock washers securing the

MXU-810/U helmet plate on the helmet shell interior surface. place helmet upright on work

bench with front of helmet closest to technician. detach MXU-810/u helmet plate from

helmet shell exterior by removing the three screws and flat washers along with fabric

cover from the underlying lock washers and t-nuts.

k. HGU-66/P, HGU-68(V)/P, HGU-85(V)/P: Place helmet upright on workbench with the front of

helmet closest to technician. Adjust helmet-mounting plate left hand-latching screw

counterclockwise until lower end of screw is flush with the inner end of the integral

threaded cylindrical nut, with the locking nut loosened. Position helmet-mounting plate

across brow of helmet, with helmet plate lower edge extension resting level across the

upper edge of helmet shell brow edge roll. Align mounting plate centering arrow with

center of upper MXU-810/U helmet plate-attaching slot. (1) Visually verify alignment of

helmet mounting plate-centering arrow with upper attaching slot and that the lower edge

extension is resting on the upper edge of the helmet shell edge roll. Hold mounting plate

firmly in place on helmet brow and tape in place with masking tape applied

to the mounting plate and helmet shell on the left and right side of the goggle mount. (2)

Position helmet with left hand side to technician. Lift “over center” latch and

insert head of latching screw into the center cut-out of the left hand mounting bracket

(thick concave bracket), close “over center” latch, ensuring head of latching

screw remains centered in left-hand bracket

cut-out.

(3) Position concave surface of left mounting bracket flush with surface of helmet shell,

with head of latching screw centered in cut-out, inner edge of mounting bracket parallel

to the left edge of the helmet mounting plate. Holding bracket in place, outline mounting

bracket position on exterior helmet shell surface, place a mark at the center of the upper

and lower slots to

indicate location of drilling points for attaching screws.

NOTE

The right hand mounting bracket features two latching notches, one deep notch and one

shallow notch, with four attaching screw slots. These features are incorporated to permit

minor adjustments to the helmet mounting plate assembly’s position on the helmet

shell exterior surface to individualize goggle placement to optimize eye relief and

interpupillary distance adjustments for the aircrew member.

(4) Position right hand side of helmet toward technician. Position right hand mounting

bracket with shallow latching notch down and away from front center of helmet under

latching hook, engage right hand helmet mounting plate-latching hook into bracket

notch.

(5) With firm downward pressure on hook, position concave surface right hand mounting

bracket flush with exterior surface of helmet shell. With shallow locking notch down and

away from center of helmet and inner edge of mounting bracket parallel with right edge of

helmet mounting plate, hold bracket in place and outline bracket position on exterior

helmet surface, place a mark at the center of the upper and lower attaching slots, closest

to the shallow locking notch, to indicate location of drilling points for attaching

screws.

(6) Remove masking tape from helmet shell and mounting plate, set mounting plate aside

clear of work area.

l. At each of the two marked locations on each side of the helmet, using a No. 33 (.113)

drill bit, drill a small pilot hole. Using a No. 16 drill bit, enlarge each pilot hole to

finished .177 dimension.

NOTE

Apply a small amount of RTV to the first few threads of attaching screws of the left hand

mounting bracket prior to installation. Application of RTV to the right hand mounting

bracket-attaching screws will be accomplished after final goggle fit and alignment checks.

m. Position backing plate, with flat surface of backing plate toward interior surface of

left hand side of helmet align built in nuts with two drilled left-hand bracket holes. On

the left side exterior, position left hand bracket, with center cutout toward top of the

helmet, over drilled holes. Secure in place using a 5/64 inch hex head key and two screws

and lock washers. Repeat procedure for installation on right hand bracket, ensuring the

center notch is down and away from top of helmet.

n. Engage the right hand latching hook into the notch of the right hand mounting bracket,

fit the left hand-latching screw into the center cut-out of the left hand mounting bracket

and close the “over center” latch. If helmet mounting plate assembly is loose,

adjust left hand latching screw to provide the desired tension, ensuring the helmet

mounting plate assembly is centered on helmet, when the over center latch is closed. Once

desired is achieved, tighten lock nut to maintain proper position of latching screw.

o. For HGU-66/P helmet: Invert helmet on work bench with brow positioned closest to

technician. From rear of helmet, ensuring liner half remains centered within the helmet

shell interior, insert front half of custom fit liner firmly against helmet shell brow

edge roll. Insert back half of custom fit liner, with fabric release loops positioned to

the right and left side, ensuring the liner half remains centered within the helmet shell

interior, into rear of helmet and push into place. Using screws, flat washers , locking

washers and flanged nuts, install grometted ends of chin/nape strap to rear attaching

points on helmet shell. Attach ear cups to pile fastener fabric on interior of helmet

shell ear cup cavity.

p. For HGU-68(V)/P, HGU-85(V)/P helmets: Reinstall internal components in accordance with

paragraph 13A-75, steps 2 a. through step 6.

NOTE

During the aircrew member goggle fit process, if difficulty is experienced in obtaining

proper eye relief or interpupillary distance using installed goggle adjustments, minor

adjustments to the position of the helmet mounting plate assembly may be accomplished by

means of attaching slot selection. To adjust position of helmet mounting plate assembly

slightly

to the right (as worn), place screws in the inboard attaching slots. To adjust position of

helmet mounting plate assembly slightly to the left (as worn), install the mounting

bracket with the deep notch down and away from the center of the helmet, using the

attaching slots closest to the deep notch.

PART 2

HGU-55/P HELMET MODIFICATION KIT INSTALLATION (NSN 5340-01-442-6411)

INTRODUCTION

This document provides instructions on how to install and adjust the left and right

mounting brackets on the HGU-55/P Helmet. This installation procedure is advisory for

user/installer's convenience.

NOTE

In case of conflict, USAF T.O. 14P3-4-151 takes precedence over this document.

1. Remove the TPL Cover Assembly.

2. Remove the energy absorbing liner.

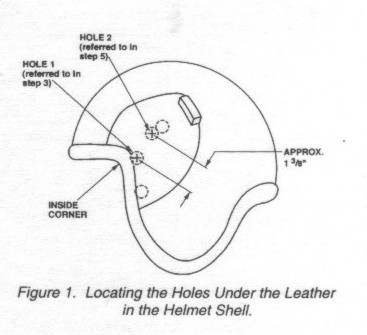

3. Locate the holes underneath the leather on the left side of the helmet. With your

fingers press on the leather and find hole 1 which is the closest hole to the inside

corner of the helmet (see figure 1). On some helmets this hole may be just at the border

of the edge roll.

4. Using a spring loaded

punch, punch a hole in the leather that covers the hole found in step 3. Using a 3/16

(.1875) bit, drill out the hole.

5. Locate hole 2 with your fingers by moving them along the helmet approximately 1 3/8

inches to the upper right of hole 1 (see figure 1).

NOTE

On some helmets, the second hole is more than 1 3/8 inches from the first hole. If this is

found to be the case. The second mounting hole must be drilled in the helmet as explained

in the following steps.

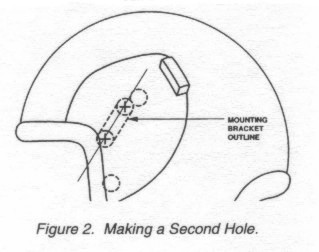

6. Place the left side mounting bracket (264345) on the helmet with the concave side

against the helmet and the notched side towards the front of the helmet.

7. Align the mounting bracket screw hole with the hole drilled in step 4. Position the

bracket along a line from the first hole, to the second hole (see figure 2). Using a

spring loaded punch mark the position for the second hole.

8. If necessary, use a 3/16

(.1875) inch bit and either drill out the existing hole or drill the required new hole.

9. Repeat steps 3 through 8 for the right side of the helmet using the left mounting

bracket as an aid.

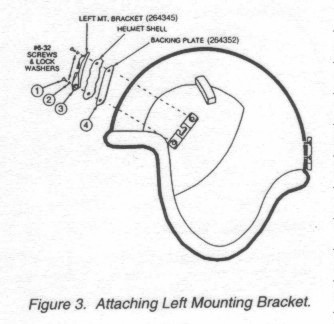

10. Position the left side mounting bracket (264345) on the outside of the helmet, concave

side against the helmet and the open end of the notch toward the helmet center line (see

figure 3) and one of the backing plates (264352) on the inside of the helmet. Secure them

in place using two screws and two lock washers. Do not tighten at this time.

NOTE

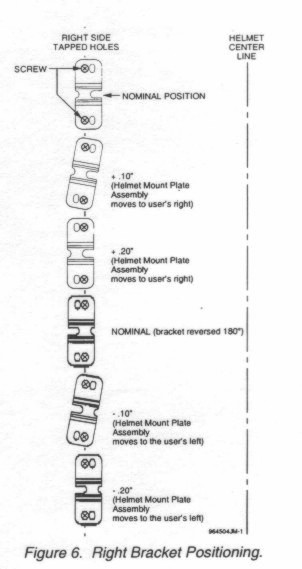

The right mounting bracket has adjustment capabilities that will be explained in step 16.

The right mounting bracket can de secured, but not tightened (at this time), in either of

the two nominal positions illustrated in figure 6.

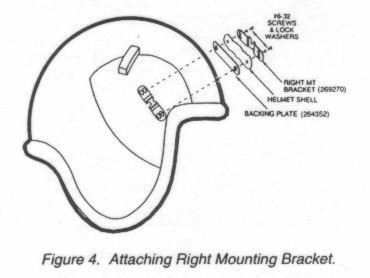

11. Repeat step 10 for the right mounting bracket (see figure 4).

12. Position each bracket such

that the holes in the brackets are approximately centred under the screw. Using a 5/64

inch Allan wrench, tighten the four screws.

13. Locate the centre line of the helmet. Mark a position approximately 2 to 2 1/2 inches

up along the centre line from the border of the edge roll.

CAUTION

The helmet mount plate assembly may be damaged if the following adjustment procedure is

not used.

14. Lift the handle of the left side catch assembly so that the handle is in the position

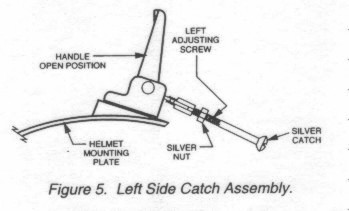

shown in figure 5.

15. On the left side catch

assembly (figure 5); loosen the silver nut on the adjusting screw to allow the adjusting

screw to move.

16. Engage the helmet mount plate assembly right side hook to the right mounting bracket

and place the helmet mount plate assembly on the helmet ensuring the moulded arrow on the

helmet mount plate assembly is aligned with the helmet centre line.

NOTE

The right mounting bracket is designed to allow the helmet mount plate assembly to be

moved ±0.20 inches laterally across the helmet. This is to accommodate variations in

helmets as well as users hose facial features require the helmet mount plate assembly to

be offset from the centre line of the helmet. Figure 6 illustrates the different positions

of the bracket and mounting screws necessary to achieve the lateral adjustment of the

helmet mount assembly.

17. Position the helmet mount

plate assembly's silver catch into the left mounting bracket. Close the catch assembly

noting that excessive pressure should not be required. The adjusting screw may require

adjustment in order to achieve a firm but not excessively firm closing pressure. Once

adjusted, tighten the silver nut so that the left adjusting screw will not move.

18. Replace the energy absorbing liner.

19. Replace the TPL Cover Assembly. |